A sustainable strategy to transform cotton waste into renewable cellulose fiber self-reinforcing composite paper

New publication by Wang, C, Su, J, Liu, T, Ge, S, Liew, RK, Zhang, H, Naushad, M, Lam, SS, Ng, HS, Sonne, C & Fan, W

Abstract:

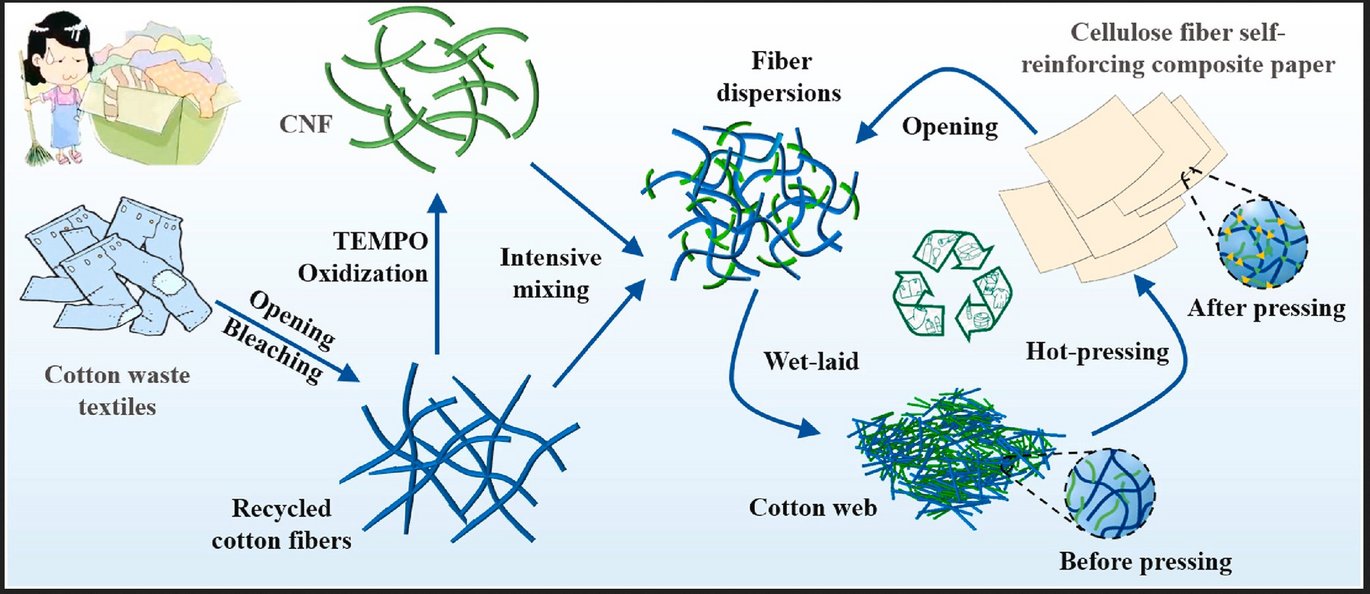

Over 100 million tons of cotton waste are produced annually, representing 35–40% of global textile waste. However, less than 30% of cotton waste is recycled annually. In particular, the fibers less than 7 mm in length dropped during the opening and carding process of cotton waste fabrics have not found a mature utilization method. This work demonstrates and reveals a strategy to transform short cotton fibers into a renewable cellulose fiber self-reinforcing composite paper (CCP). Recycled cotton staple fibers less than 3 mm were prepared into CNFs by TEMPO oxidation. The use of recycled cotton fiber (3–7 mm) as reinforcement and CNFs as a matrix results in a composite material bonded through hydrogen bonding. The recovered cotton fibers and CNFs soliquoid combine together to form a paper pulp, which is then transformed into CCP using wet-laid webs and hot-pressing techniques. When the CNF content reached 5%, the tensile strength of CCP was 86.68 MPa, which is 1.8 times that of the commercial A4 paper. The tensile strength of the CCP only decreases by 25% from the dry state to the wet state, while that of A4 paper after soaking water is almost zero. This makes CCP a special paper with broad application prospects. Since CNF extracted from cotton waste textiles is used as a strengthening agent and without any chemical adhesives added in the paper-making process, which makes the production process of CCP cleaner and can be recycled in a closed loop. Overall, the promising strategy achieves at least four objectives related to cleaner production: maximum recycling of cotton waste, CNF instead of traditional chemical adhesives used in paper-making, water recovery (internal recycling), and realising closed-loop recycling. This technology can potentially be applied to a wide range of colored papers and intelligent packaging papers in the future.